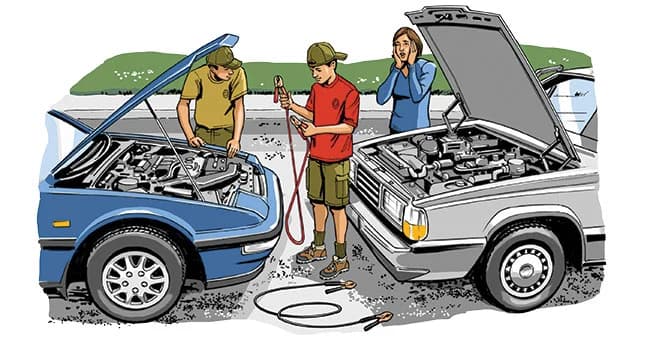

How some time spent tinkering gives Scouts the drive they need to succeed. One Saturday in May, veteran Scouter Bob Lahmers of Alliance, Ohio, and 14 counselors transformed a large part of Camp Tuscazoar near the town of Dover into a cross between a repair shop, a junkyard, and a mad scientist’s laboratory. The adult volunteers set up stations at the camp where Scouts could get their hands dirty working on the Automotive Maintenance merit badge. At one station, Scouts encountered a freestanding engine they could operate by hand, turning the crankshaft to watch the pistons move up and down. At another, a representative from Matco Tools, an Ohio-based manufacturing firm, showed off a truck that was loaded with, well, a truckload of automotive gadgets. “Everything we had was great,” Lahmers said. “It went off like a bang.” As did a bunch of airbags. A salvage yard had donated six airbags from totaled cars, and Lahmers’ team deployed them to show the Scouts how they work. “We put a bucket on top of one and blew it about 65 or 70 feet up,” Lahmers said, laughing. The team’s counseling that day, part of an annual event featuring fun and educational activities for area Scouts called Dover Dam Weekend, might seem over the top. But it demonstrated an effective approach to teaching the skills required to earn the Automotive Maintenance merit badge: Get the Scouts’ attention, let them work with the equipment, and finally get around to signing off their requirements. Jack Auld took a similar approach when he taught Scouts last spring at a merit badge day sponsored by his unit, Troop 772 in Laguna Niguel, Calif. While Auld didn’t use disembodied engines or inflating airbags, he had a modern alternative: videos from the Internet. Using those resources, Auld put together a comprehensive PowerPoint presentation to explain a car’s various systems, from air intake to exhaust. Dividing his class into two sessions, one in a classroom and the other hands-on, Auld was able to let the Scouts put theory into practice—though the lines between them often blurred. When Auld talked about tires, for example, he showed a cutaway illustration of a tire. But he also had an actual tire so the boys could learn to decipher the specifications on the sidewall. “The more you can get them out of their seats and looking at something,” Auld said, “the better.” Automotive Maintenance, like many merit badge skills, was at least partially designed to introduce Scouts to potential careers. But Auld, who worked his way through college as a mechanic and then spent years in the motorsports business, recognizes that nearly all the boys he counsels plan on choosing another line of work. Still, most all of them will drive to their jobs in cars or trucks. In fact, Troop 772 meets just a few miles from Interstate 5, where 265,000 vehicles travel every day. So Auld focuses on teaching Scouts to become knowledgeable consumers, rather than pushing them to become mechanics or mechanical engineers. “It’s a good opportunity to help them understand something that’s a vital part of their lives and not be intimidated by it,” he said. “In my mind, that should be one of the primary goals—to take away the fear of the unknown.” Add a little grease under the fingernails, and you’ve got the makings of a great merit-badge experience.